Intercooler - After 1000 Hr Service

All modern marine diesel propulsion engines will use forced induction to increase engine output and reduce emissions. Air leaving the turbocharger is compressed and therefore superheated to 3 or 4 times ambient air temperature. This air is too hot for the engine to digest and must be circulated through the intercooler. Intercoolers have an important job because the marine diesel engine must have a clean, cool and constant flow of air to run efficiently and safely.

The intercooler, like the cooling water heat exchanger, has a seawater side. The sea water exchange in the intercooler reduces the air temperature back to near ambient and in some latitudes leaves it much cooler. Because intercoolers collect debris and sediment, they need maintenance.

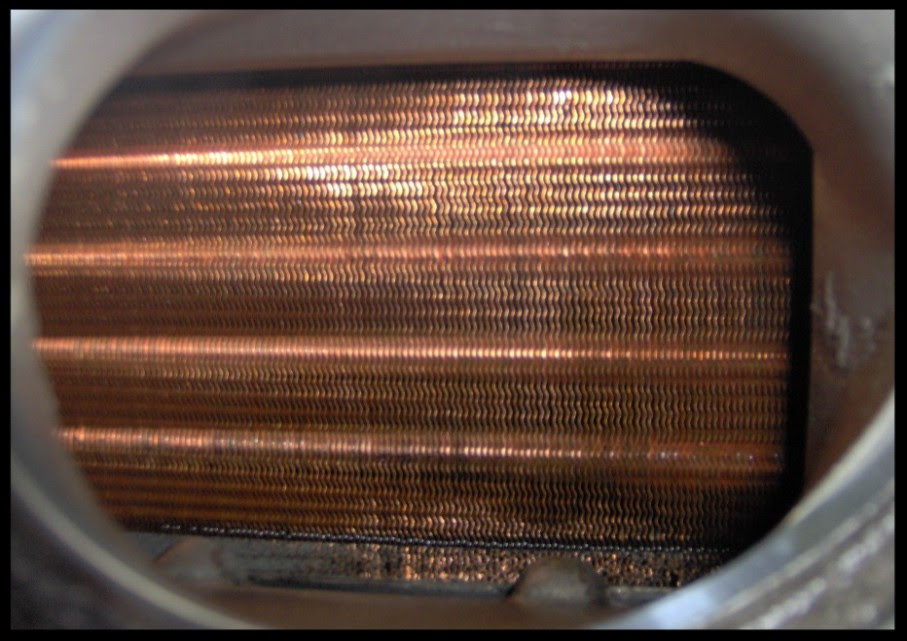

The intercooler also has an airside. The air side of the intercooler has the unique situation of being subjected to superheated crankcase vapors which are regularly evacuated by breathers operating under a partial vacuum from the inlet side of the turbochargers. These crankcase vapors contain motor oil and unburned diesel fuel. Because the air filters do not block 100% of the salt air, there can be some salt residue ingested during normal operation as well. The result is build-up on the air side cooling fins in the intercooler. The air side of the turbochargers, the pipes, and manifolds which carry the air to the intercooler also get a lot of build up. The turbochargers lose efficiency due to speed loss when the compressor wheels and housings are dirty.

MAN intercoolers have side covers that need to be removed on a routine basis and have the gaskets replaced and the fasteners cleaned or replaced. If you go too long without service, the disassembly could become more difficult with broken bolts and expensive trips to the machine shop for repair!

The sea water and airside deposits and the side covers are all addressed during the intercoolers service. The 1000Hr service is vital to keeping your engines running efficiently. This service is key to running your boat with fewer issues in the long run.